Jatco JF015E: a CVT That Is Crazy About Cleanliness

Automatic transmissions are supplied to Nissan by JATCO. Today, it is the world's leading manufacturer of CVTs for automobiles – the company manufactures almost half of such transmissions worldwide. The Jatco JF015E model is designed for up to 180 Nm torque transfer and intended for compact passenger cars with the 1.8 L or smaller engine size. In the Russian market, it is common in the gasoline-powered Qashqai and Juke. Those involved in Nissan repair, also known CVT under Nissan's number RE0F11A. Nissan's employees often call JF015E "small" to distinguish it from the "big" JF011E, which is able to transmit torque of up to 250 Nm and be installed on the more powerful Qashqai models.

JF015E: Smaller, Lighter But More Complex

CVT is just a part of the JF015E design. This transmission also has a torque converter and a compound epicyclic reduction gear. Such a complex design solution is necessary to reduce the gearbox size and simultaneously increase the gear ratio. If this ratio is expanded with the employment of CVT only, it will grow in size. JATCO's engineers chose a different way – they supplemented CVT with a compound epicyclic reduction gear and a torque converter. This allowed making both CVT and the whole gearbox smaller in size. Torque converter became thinner, too. As a result, this transmission is 10 percent shorter and 13 percent lighter than the JF011E. Therefore, Nissan, Suzuki and Mitsubishi were able to employ it in compact front-wheel drive models.

CVT is based on push belt and tapered pulleys that transmit torque, with transmission gear ratio changing due to the approach and expansion of pulleys.

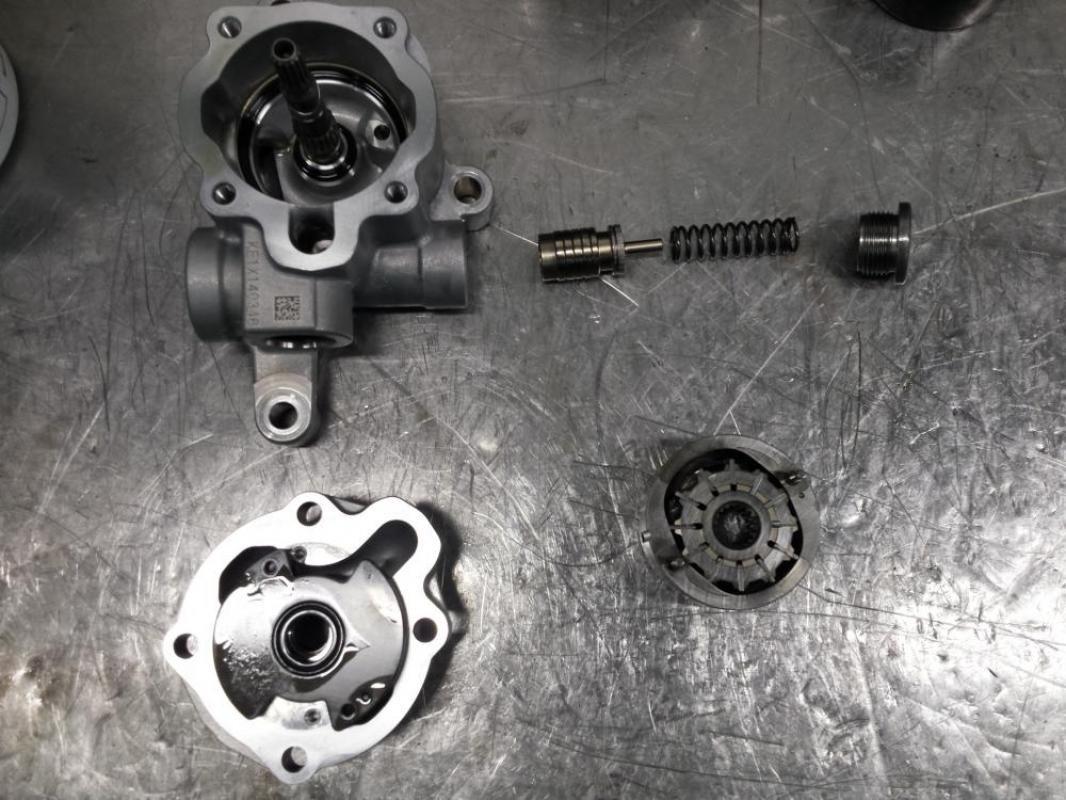

Pressure in the system is created by vane-type pump with a roller-chain drive.

A major difference of the JF015E from the JF011E is that the compound epicyclic reduction gear has two stages to move forward. They switch automatically, the driver is not involved in the switching process. Epicyclic gearbox is controlled by friction clutch and a brake that serves to activate reverse gear. The possibility of activating reverse gear without changing the direction of CVT pulleys rotation is to increase its service life due to lower loads in case of frequent switchings, for example, in constrained parking, when the car moves back and forth for a while.

More complex design as compared with other CVT transmissions has not reduced the reliability of the JF015E versus other solutions – both torque converter and reduction gear create no special problems. At least not more than any other torque converters and epicyclic gearboxes. Yet the JF015E has its typical "diseases," too.

Harmful Filings

A common complaint of the car owner is irregular motion, kicks at acceleration. There may be several reasons behind this kind behavior of a car. However, virtually all of them have to do with oil contamination with the pulley debris – metal chips or filings can create a variety of problems. There are magnets in the crankcase to mitigate harmful effects of these metal particles, they have to collect these particles but sometimes do not cope with the task.

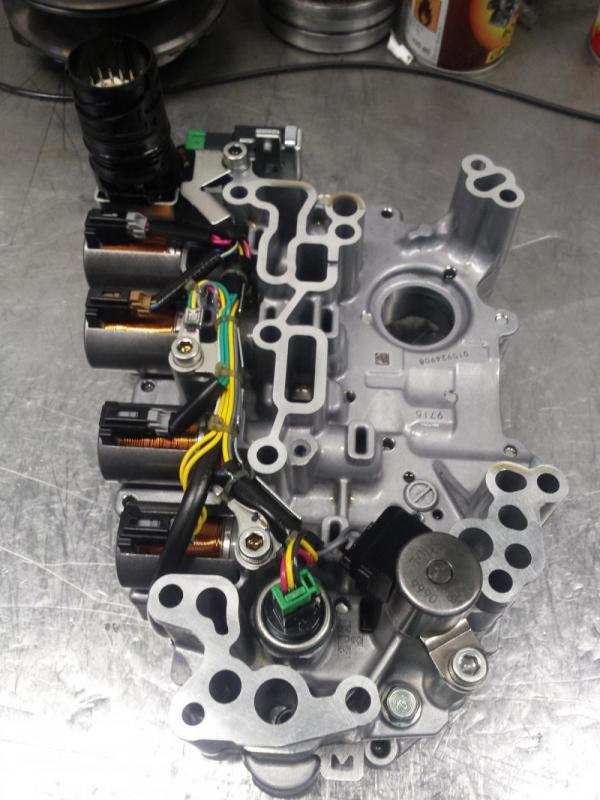

This may cause various malfunctions. First of all, accelerated wear of the valve body leading to pressure fluctuations, which, in turn, make pulleys move, resulting in the fluctuations of transmission gear ratio and irregular motion of the car.

Normally, this also leads to shock at reduction gear range change (at an approximate speed of 30–45 km/h), as well as double or even triple range switching, that looks like engine revolution surges, reluctance to go back to lower range at braking, vibration at switches to lower range – all of these are consequences of "leaky" plate with significantly worn down body and valves. The valve body needs to be repaired and possibly even replaced.

Filings and chips also cause irregular wear or seizure of the oil pressure relief valve.

Pic.: Oil pressure relief valve and its matching bore with traces of scoring

This type of defect can occur fairly soon, in cars with not more than 30–40 thousand km on the odometer.

Unless the valve body is repaired or replaced in time, this will ultimately cause damage to pulleys and belt that will have to be replaced in this case. Pulleys are the most expensive unit of the CVT. They can be polished but in some cases only replacement can help.

Metal contaminants also block up pressure controllers, thus contributing to an accelerated wear of valves.

Timely oil change and a mandatory installation of new filters can help avoid these problems. It is better not to experiment with oil and to use only NS-2 or NS-3, the CVT Fluid recommended by Nissan.

Wear and, accordingly, oil contamination get stronger if the driver starts off when the engine is cold. Pulleys and push belt wear off quickly at slip (at this very moment filings and chips occur). Modern engines do not need to be run in, although they do not like abrupt loads in cold, but it is very bad for transmission. It is recommended that the driver move smoothly during the first few minutes.

In some cases, irregular acceleration can be caused by engine issues but transmission hydraulics problems are more likely.

New Details

The "elder" CVT JF011E encounters difficulties due to oil contamination with debris. JATCO's engineers attempted to save the new model from some of them by changing certain units.

For instance, the JF011E employs stepper electric motor to control pressure, changing the position of the valve which controls pressure in pulleys to change transmission gear ratio. In the JF015E oil pressure balance in pulleys is controlled by solenoids. Solenoids are less prone to contamination with chips but it is possible, too.

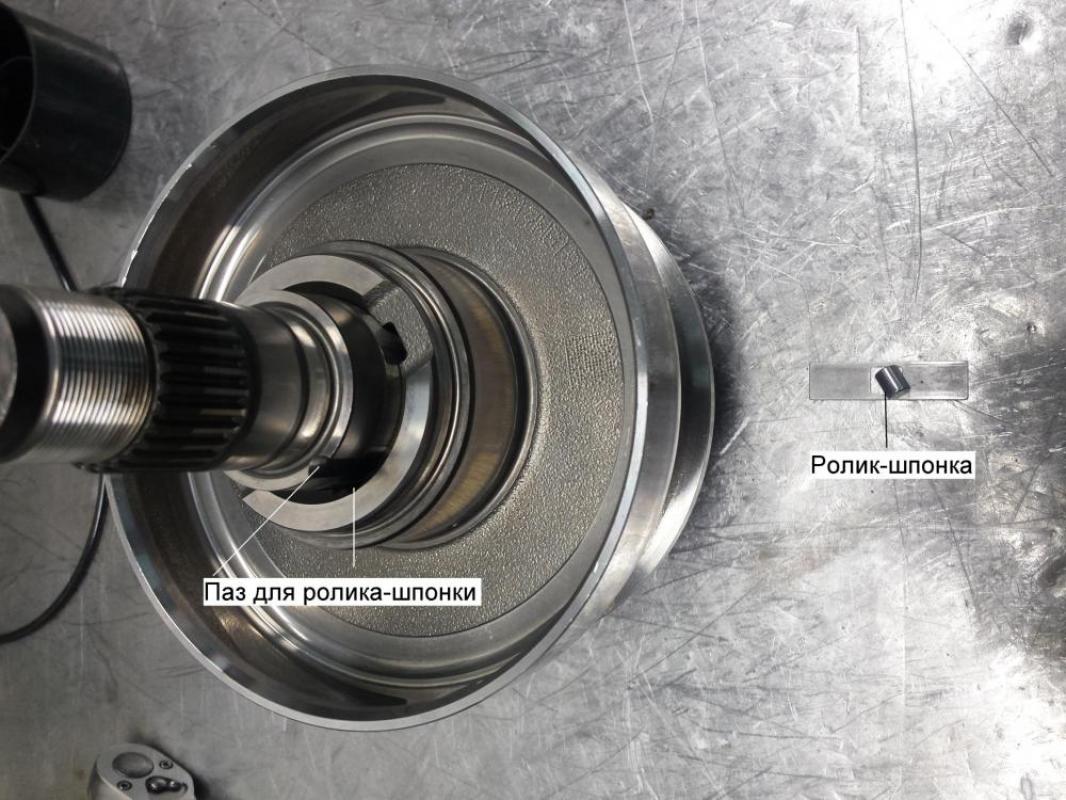

The design of guiding pulleys has changed, too. In the JF011E, pulleys are attached to the shaft with balls, which could be destroyed by constantly changing loads. And here it is pulleys that are fixed with the roller. This is a more durable design solution, which reduces the likelihood of pulley seizure.

Full Speed Astern!

The most obvious failure of the JF015E is its reluctance to move forward when the selector is in D position (while reverse gear is active).

This is caused by a breakaway of the reduction gear's sun wheel from the spider. As it is not involved when the car is started in reverse, its breakdown does not prevent the car from rolling back. Sun wheel operates at high loading, while being welded to the spider. The only option is replacement – and full speed ahead! Since this is a fairly common failure, it is recommended that the condition of sun wheel be checked during other operations relating to the JF015E disassembly. If you notice any cracks in the spider, it is better to replace the sun wheel immediately.

The next failure also has to do with the upgraded parts as compared with the previous transmission models: the input shaft rotates on the bearing, which is often destroyed by overheating as it has a closed design and is not cooled by oil.

They chose not to open it due to its low bearing capacity and low viscosity level of the service transmission fluid. This type of defect first manifests itself in shaft rotation noise, when the engine runs idle and the selector is moved to P position.

If this noise is ignored, the input shaft end float causes damage to the input shaft aluminum stator, a seal dividing the torque converter lock piston cavity and the torque converter itself. The torque converter body can even balloon due to excessive pressure and, accordingly, will have to be replaced.

Failing bearing often damages its seats – the input valve and a significant part of the body. In this case, a new original bearing can no longer be installed. In certain cases, unless damages are fatal in nature, it can be replaced with a larger bearing.

Our recommendation for the owners of cars equipped with the JF015E is to be more attentive to noise – as a rule, this is the first sign of mechanical damage. Moreover, if you notice odd discontinuity of revolutions and irregular acceleration, do not wait for everything to work itself out, it is better to check the transmission condition and, probably, change oil and replace filters. This will help extend the service life of unit.

About JATCO

Japanese Automatic Transmission Company was established in 1970 as a joint venture of Nissan, Ford and Toyo Kogyo (later known as Mazda). Since 1989, it has been called JATCO. Then the company took over the automatic transmissions and CVT production subdivisions of Nissan and Mitsubishi Motors. Today, 75 percent of JATCO are owned by Nissan; 15 by Mitsubishi Motors; and 10 by Suzuki. The company supplies its products to virtually all automobile manufacturers of Japan, with the exception of Honda and Toyota, which prefer their in-house transmissions. Since 2012, the Jatco JF414E automatic transmission has been installed on LADA, as well as Datsun made in Russia. JATCO has branches in Mexico, France, Korea and Thailand.

JF015E : Top Performer

The Jatco JF015E CVT has been produced since July 2009. In August 2016, its output exceeded 10 million pieces. Jatco JF015E is manufactured by the JATCO plants in Japan, China, Mexico and Thailand.

Installed on the following models:

Nissan – Qashqai, Juke, March, Latio, Sylphy, Cube;

Suzuki – Swift, Splash, Wagon R;

Mitsubishi – Mirage, Delica.