Lineartronic TR-580: Subaru’s most popular CVT

The name “Lineartronic” is used for two Subaru transmissions – the TR690 and the TR580. They are both based on a chain variator. There is also a torque converter – to broaden the range of gear ratios and to ensure a smooth start-off.

The name “Lineartronic” is used for two Subaru transmissions – the TR690 and the TR580. They are both based on a chain variator. There is also a torque converter – to broaden the range of gear ratios and to ensure a smooth start-off.

The Lineartronic TR580 is 100 mm shorter and 15% lighter than the TR690, and that is the reason why the latter is hardly used nowadays, and only with very powerful engines. The two transmissions differ in their configurations: the TR580 valve body is mounted on top of the transmission, the forward and reverse clutches are located in front of the pulleys, whereas in the TR690 they are located behind them, and the input clutch and the secondary planetary reduction gear have been eliminated from the CVT’s design.

The power flow on the TR580 is also different: it goes through the input shaft, which has the forward clutch attached to it. The reverse clutch and the planet are located in front of the primary pulley. This means that the direction of the pulley rotation changes when switching between forward and reverse. Apart from that, having the clutch in front of the pulley reduces the engine parasitic drag in Neutral and Park, because the pulleys aren’t rotating in those ranges, as they are in the TR690.

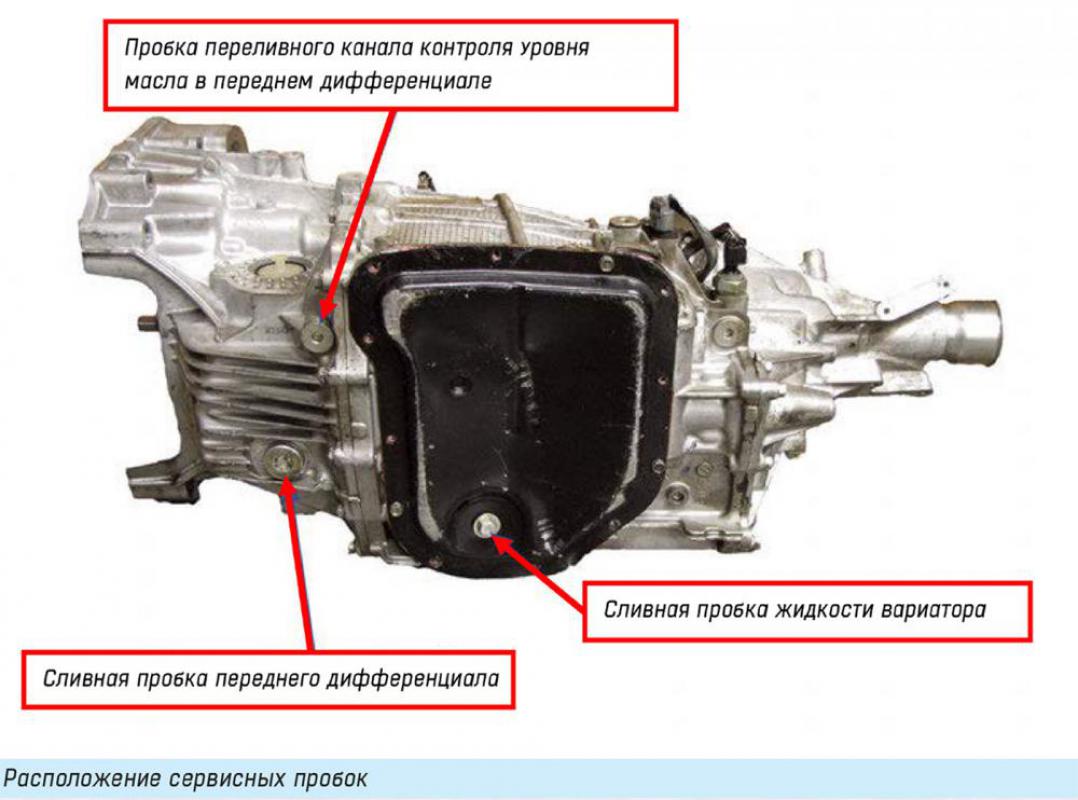

The main servicing procedures for this transmission are CVT fluid change and front differential oil change. Both operations should be done in strict accordance with technical requirements – the fluid operating limit is 120,000 km. You also have to control its level and condition at every other maintenance service, that is every 30,000 km, and add it if necessary. If the fluid grows cloudy it needs to be changed. When the vehicle is constantly operated at low temperatures or there are frequent trips off the road, across mountainous terrain, the manufacturer recommends changing the fluid after every 45,000 km. Fluid fouled by wear products can prompt solenoid wear in the valve body.

CVT fluid change Subaru TR-580

To service the transmission, remove the 14mm drain plug on the pan (Fig.9). The filter is a metal mesh located under the pan, it is serviceable and can be washed. Reinstall the filter and the pan using a sealant and tighten the drain plug to 30 Nm.

Use a Subaru CVTF fluid – from 11.9 to 12.4 L for complete replacement (on a dry fill). To fill the transmission:

- Remove the fill plug with an 8mm Allen socket (Fig.10).

- Fill the transmission until the fluid drips out of the fill plug.

- Start the engine and run it through the gear ranges.

- Let the transmission fluid warm up to between 35–45 °С.

- Add more fluid to the transmission until its level reaches the bottom of the fill plug.

- Torque the fill plug to 50 Nm.

Front differential oil change Subaru TR-580

Among the main causes of ring lockers failure is a delayed or improper oil change in the front differential.

There are plugs on the differential case that look the same, and it is easy to mistake them for one another. For draining the oil from the front differential there is a drain plug on the bottom. The check overfill plug is located near it, also on the bottom of the front differential case (Fig. 9).

- Use a T 70 torque bit to drain the oil (Fig.9).

- After the fluid drains, reinstall the drain plug and tighten it to 70 Nm.

- Remove the check overfill plug with an 8 mm Allen socket (Fig.9).

- Remove the fill plug on the passenger side of the transmission with an 8mm Allen socket (Fig.11).

- Fill the front differential with 75W-90 gear oil until it starts dripping out of the check overfill plug in the bottom part on the differential.

- The front differential requires 1.35 L of 75W-90 gear oil.

Transmission teardown (Subaru TR-580)

The disassembly of the transfer clutch case is similar to the TR690 and does not present any difficulties. This procedure was covered in detail in the previous issue. It is on the next stage that the differences between the two Lineartronic models appear. After removing the transfer clutch it is necessary to take down the parking mechanism, and then you can remove the transmission case. Now we can see the CVT pulleys, the secondary pulley is covered by a baffle, which will also have to be taken down.

Be careful with the clips on the plastic chain guides, they are easily breakable.

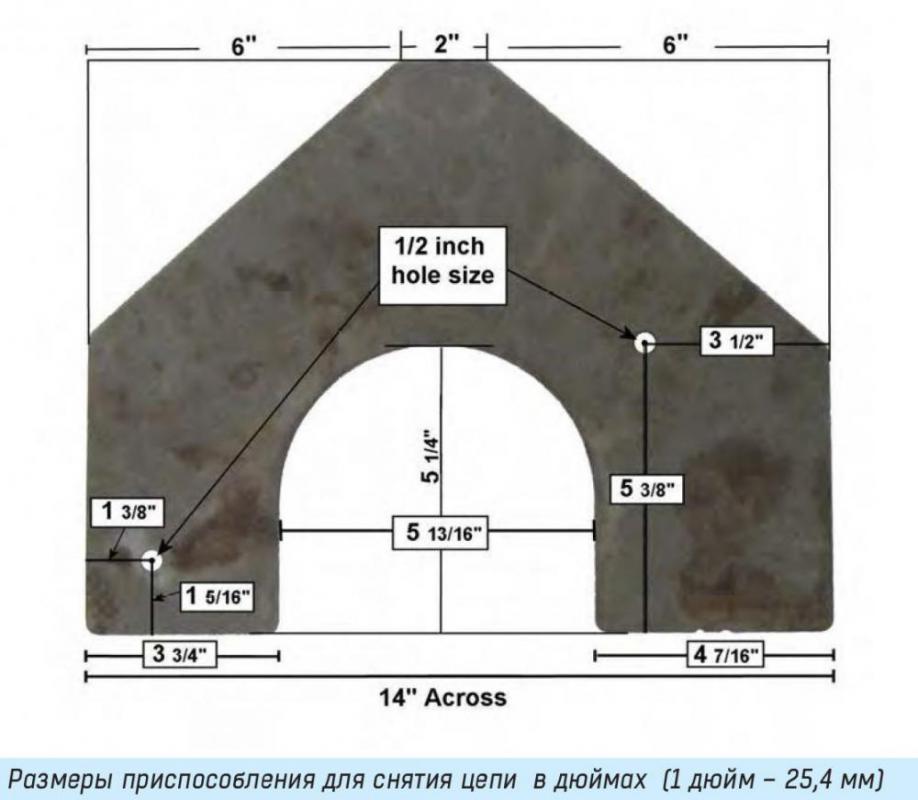

You will need a special device to remove the chain. The original Subaru tool is very expensive, but you can easily make it yourself from a 4.7mm steel plate. Please note that the dimensions in the picture are given in inches!

You need to take special care while disassembling the pulleys, because under the retainer there is a large spring (which is very strong).

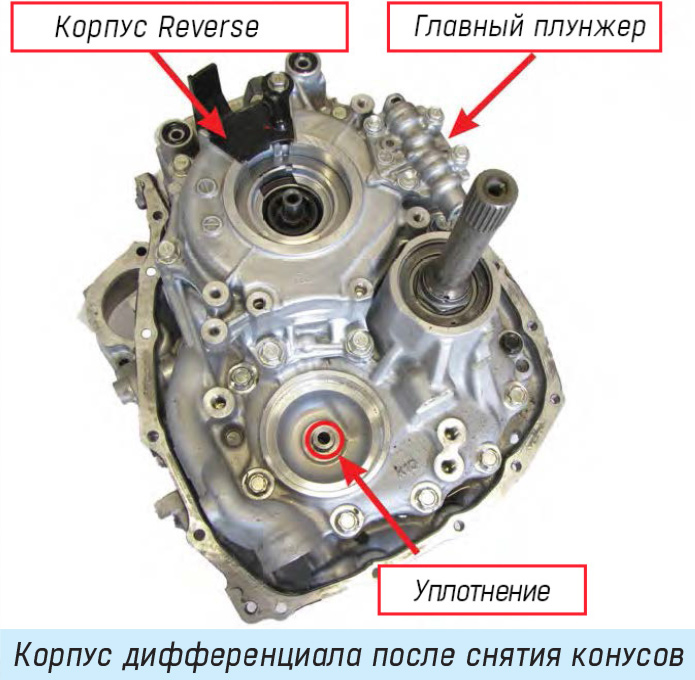

After removing the chain you can take down the pulleys. Then remove the manual valve case, and the reverse clutch case.

Pay special attention to the position of the Belleville spring in the reverse clutch, a similar one is also located in the forward clutch.

After removing the reverse clutch, you can see the planet. The sun gear is to be installed with its groove into the drum!

Then you can take out the input shaft assembled with the forward clutch.

After that you remove the front differential cover together with the output shaft. Dismantle the front differential and take it out of its case. While doing it, take special care removing the nuts of the front differential bearings. They regulate the starting torque of the differential bearings, and also the differential position against the output shaft – it’s one of the adjustments of the contact area of the hypoid gear. When assembling it back together they will need to be reinstalled in the same position they were in. Therefore before removing them, note their position against the case and while removing count the number of turns (and write it down).

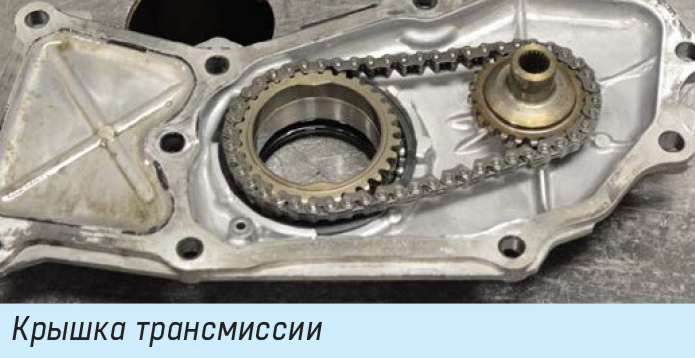

Then you remove the transmission front cover and finally get access to the oil pump which should also be dismantled and inspected for wear.

How to remove the valve body of Subaru TR-580

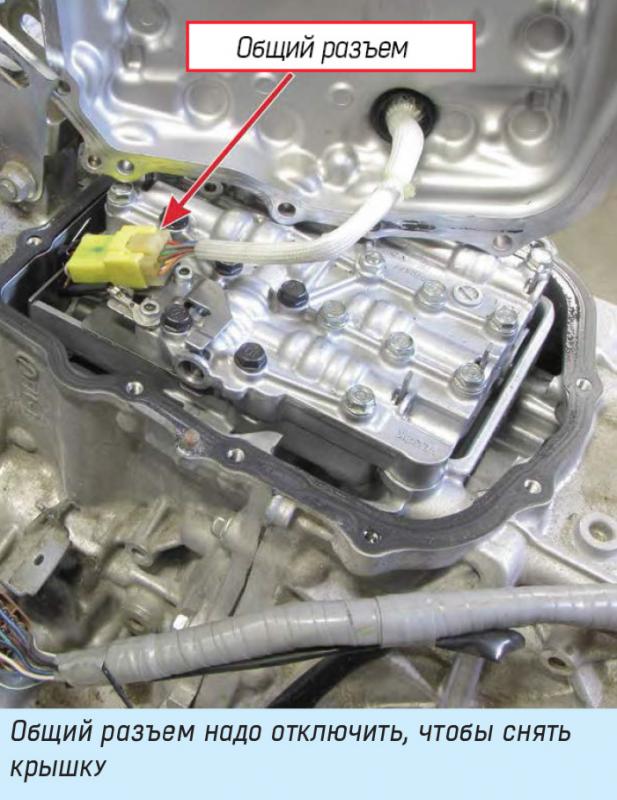

The Lineartronic TR580 valve body is located on top of the transmission case. This makes it difficult to take down the valve body without removing the transmission from the vehicle, but it is still possible.

First you need to remove the sound insulation located above the valve body cover, then thoroughly clean it and blow through it to remove dust and dirt from the cover and the place where it comes together with the transmission case. It is necessary to prevent dust and dirt from getting inside the transmission when opening the cover. After unscrewing the cover, you need to lift it and unplug the solenoid connector located under the cover. After that the cover can be removed, thus opening access to the valve body.

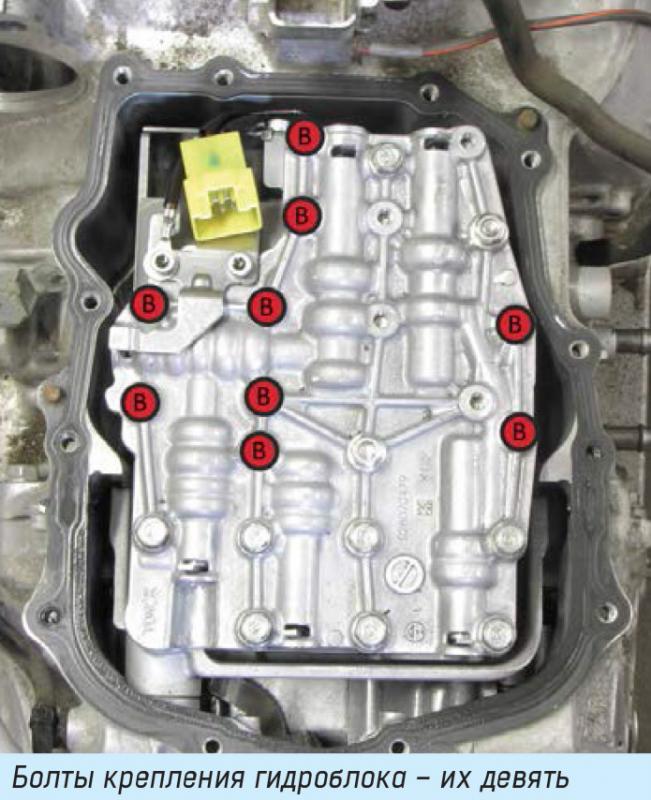

Then remove the nine bolts fastening the valve body to the transmission case (in the picture they’re shown in red).

Watch for the two case passage O-rings that may fall out.

Solenoids of Subaru TR-580

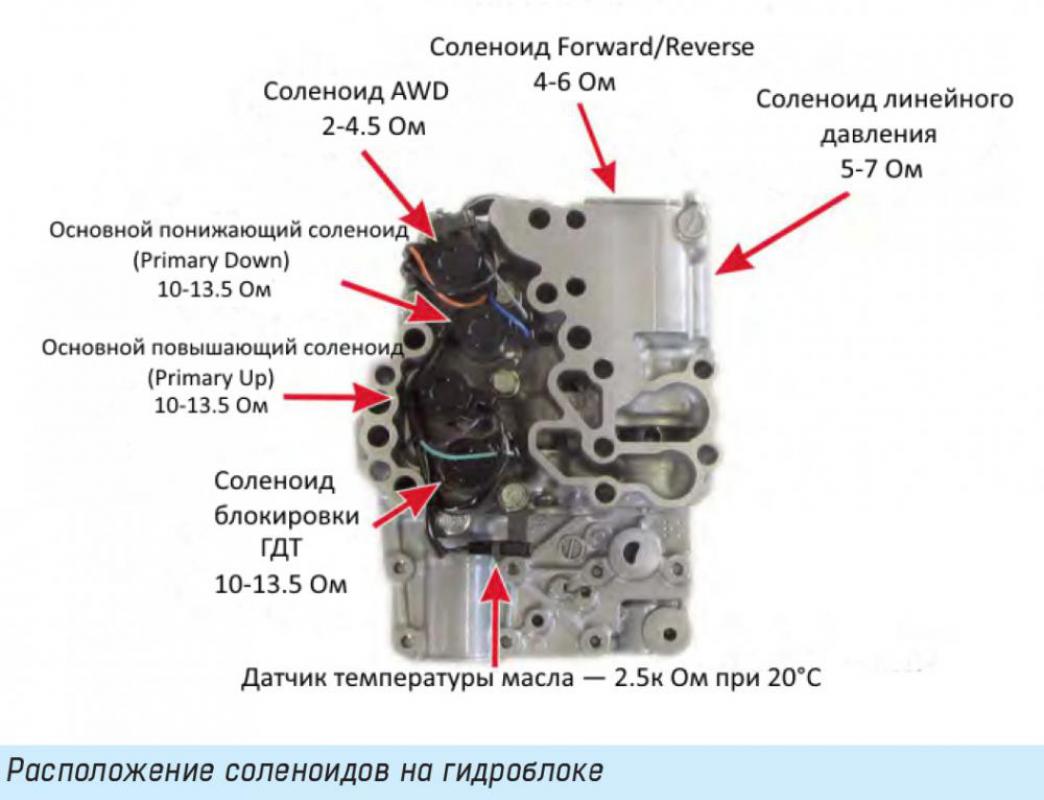

The transmission is controlled by six solenoids, which are located in the valve body.

A fault in solenoids is often the result of a delayed fluid change and operation in extreme conditions and under excessive loads. The manufacturer recommends that official dealers should change them all at once, because the TCM “sees” even the slightest inconsistencies and throws an “error” message.

– The Secondary Line Pressure Control Solenoid – regulates the fluid pressure in the transmission, it’s located inside the lower part of the valve body, the control wire is red, it’s grounded on the valve body case.

– The Forward / Reverse Solenoid – controls the Forward / Reverse regulating valves, and depending on the position of the valve directs the fluid to the corresponding clutches (forward or reverse); it is located in the middle section of the valve body, the control wires are gray and white.

– The Lock-up Duty Solenoid – controls the position of the lockup control valve, the wires are light-green and gray.

– The AWD (Transfer Clutch) Solenoid – regulates the oil pressure in the transfer clutch, the control wires are black and orange.

– The Primary-Up and Primary-Down Solenoids work together – they control the CVT ratios and regulate the pressure in the pulleys. The primary-up solenoid wires are black and purple, the primary-down solenoid wires are gray and light-blue. The oil temperature sensor is built into the internal wiring.

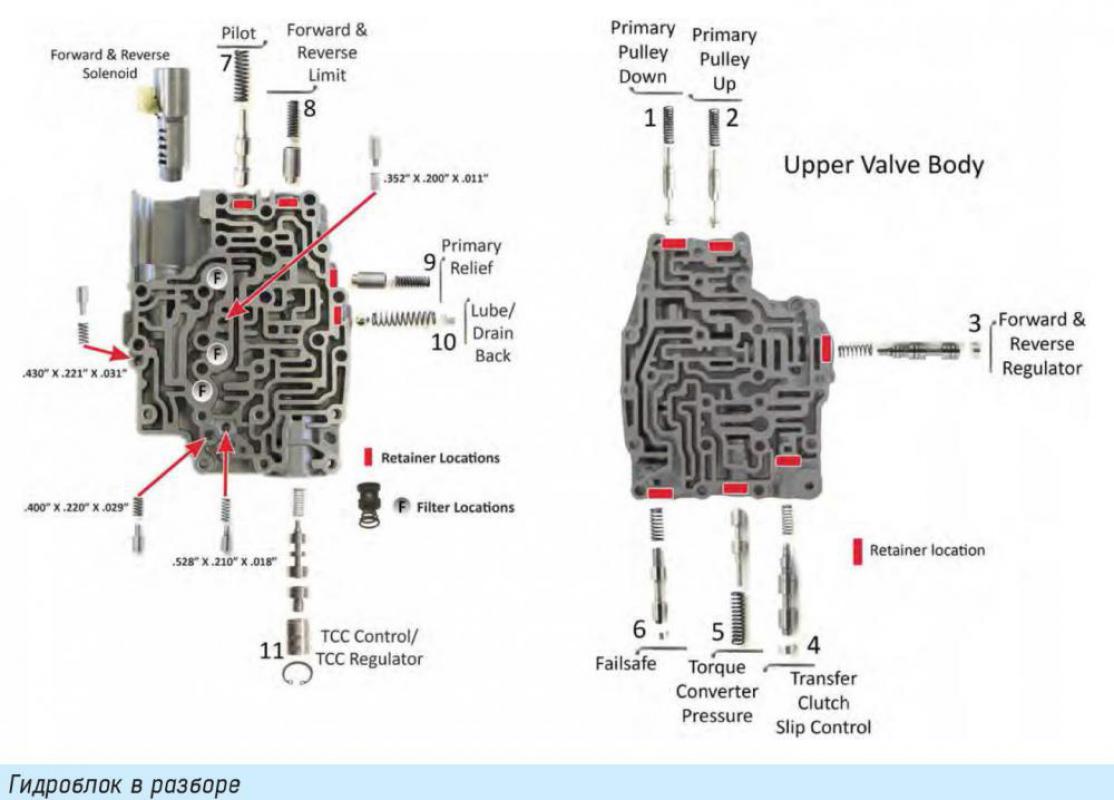

In the pictures you can see the disassembled valve body. In the table below the valve and wire dimensions are given.

Other failures of Subaru TR-580

Other units can also present problems. For instance, the torque converter can get out of order, but if it needs rebuilding – entrust it to professionals. In the previous issue it was described how to remove it. A particular problem of the Lineartronic in cold weather conditions is fluid leakage through the torque converter seal. It is easy to identify by traces of oil.

Abnormal noises during transmission operation while driving are caused, as a rule, by the chain wear, the breakdown of the guides and the interference of the chain with the oil supply tubes, which leads to their wearing out and loss of oil pressure. To rectify this problem, it is necessary to replace the chain together with all the guides, as well as the oil tubes.

Aleksandr Potapov